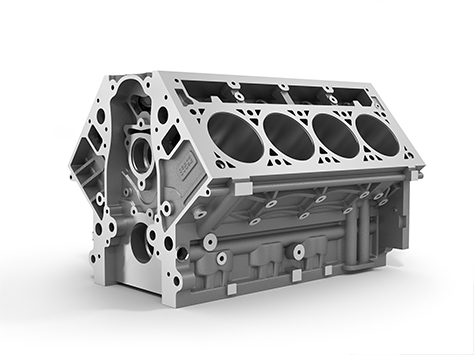

As one of the most challenging engine components, the crankshaft involves multiple production processes using complex custom tools. Essential for translating reciprocating linear piston motion into rotation, crankshafts require the highest quality control and strict tolerances

IKEN offers deep hole drills with crankshaft hard car PCBN blades.

1 - Outer circle and end turning

Solution: The use of IKEN/ISO alloy blades maximizes the metal removal rate for this application. Its advantages include reliable accuracy and higher efficiency.

Product:IKEN ISO blade

2 - Milling irregular allowance

Solution: IKEN non-standard ball end milling tools provide long and predictable tool life with internal cooling channels to maximize machining performance.

Product:IKEN alloy milling cutter

3 - Large number of holes

Solution: Well Research Easy drilling series products to meet the fast, high quality and reliable high volume drilling

Product:IKEN drilling

4 - Various reaming

Solution: IKEN non-standard reamers provide long and predictable tool life with internal cooling channels for maximum machining performance.

Product:IKEN non-standard reamer

5 - Deep hole drill

Solution: IKEN non-standard deep hole drilling provides long and predictable tool life with internal cooling channels to maximize machining performance and meet fast machining beats.

service@service.com

Qingpu District, Shanghai

Shanghai Jingyan Precision Tools Co., Ltd